WIRELESS CHARGING IN THE NEWS

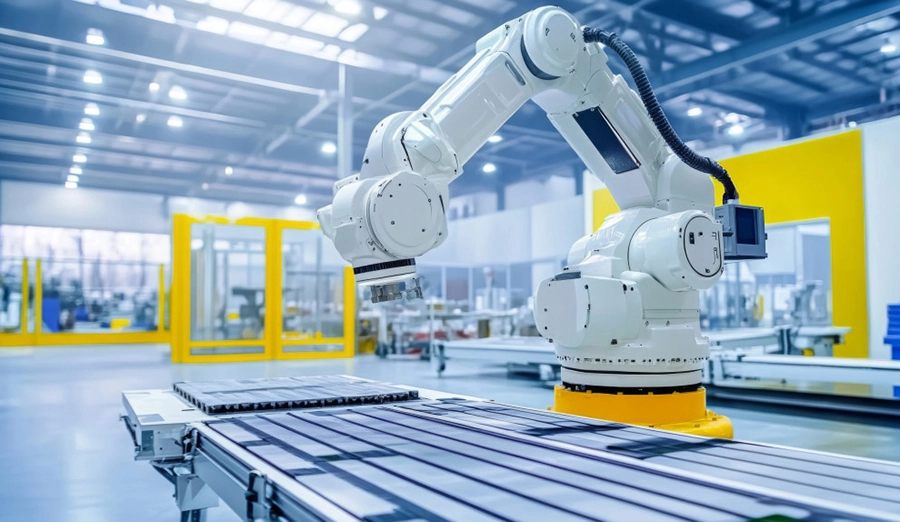

In the warehousing and logistics industry, the wave of intelligent transformation is sweeping the world. Automation equipment such as AGV, AMR, and sorting robots have gradually become the "new labor force" of warehouses, but problems such as waiting for shutdown, manual intervention, and security risks brought about by traditional charging methods are becoming invisible bottlenecks restricting efficiency improvement. How to make the robot really achieve 24 hours of uninterrupted work? A new generation of wireless charging solutions for warehousing and logistics is opening up new possibilities for the industry with disruptive technologies.

First, wireless charging: redefine the robot "endurance freedom"

Traditional plug-in charging requires the robot to frequently return to the fixed point, each charge needs to stop for more than 30 minutes, and manual plugging also has the risk of leakage. Wireless charging technology through the principle of electromagnetic induction, so that the robot only needs to stay in the charging area can automatically replenish the power, to achieve "non-inductive battery life". This "stop and charge" mode can increase the effective working time of equipment by more than 20%, more completely liberate human supervision, and truly build an intelligent storage system that runs all day.

Second, the six robot application scenarios are fully adapted

1. AGV/AMR handling robot

In the main force of high-frequency round-trip handling between the raw material warehouse and the production line, by embedding wireless charging boards at key nodes on the ground, the robot can automatically recharge when waiting for loading and unloading, avoiding the waste of transport capacity caused by no-load return charging. According to the measured data of an auto parts warehouse, the average daily transportation trips of bicycles increased by 35% after the deployment of wireless charging.

2. Intelligent sorting robot

An invisible charging belt is deployed around the sorting workstation, and the robot can complete energy supplement in the sorting gap. Combined with dynamic power regulation technology, it can not only meet the needs of fragmented charging in high-speed sorting scenarios, but also avoid electromagnetic interference affecting the scanning accuracy.

3. High storage robot

For vertical handling robots that climb shelves in three-dimensional warehouses, a customized thin charging module is embedded in the shelf layer. The robot automatically aligns the charging interface when accessing the goods, overcoming the charging problem of high-altitude operation and improving the storage utilization rate.

4. Unmanned forklift truck

High-power charging boards are laid on the loading and unloading platforms and charging areas to support the quick recharge of 3000kg forklift trucks. The IP67 protection level ensures safe operation in rainy outdoor scenes, and the charging efficiency is 50% higher than that of the traditional battery change mode.

5. Inspect the security robot

Multiple micro-charging points are set in the inspection path, and the robot can autonomously complete the "energy relay" according to the preset route. A 3C electronic warehouse application case shows that wireless charging expands the effective inspection range of security robots by 3 times.

6. Logistics drones

The special charging apron for drones is deployed on the roof of the warehouse, and the automatic positioning system is used to realize charging upon landing and flying upon full charge, providing a new solution for short-distance distribution in the park.

More than charging: the ecological value of smart storage

Our wireless charging system adopts modular design, which can flexibly configure different power schemes of 5W-30kW according to the warehouse layout to meet the voltage requirements of various industrial robots. The intelligent energy management platform monitors equipment power in real time, automatically plans the optimal charging strategy, and can be seamlessly connected with WMS and ERP systems, making energy management a digital base for smart warehousing.

Core strengths enable:

Millimeter accurate positioning, charging efficiency of more than 92%

Foreign body detection + overtemperature protection dual safety mechanism

The daily charging cycle of a single device can reach more than 50 times

1 hour fast deployment, old warehouse transformation without shutdown

In Zhejiang, an average of 100,000 units of e-commerce warehouse were shipped a day, and after the deployment of wireless charging system, the overall efficiency of the robot team was increased by 28%, and the annual operation and maintenance cost was reduced by 1.9 million yuan. This is not only an upgrade of technology, but also a revolutionary evolution of the storage operation model.

Act now to seize the intelligent logistics highland

As a global standard-setter for industrial wireless charging, we have provided energy solutions for more than 500 smart warehouses in 23 countries. Whether it is planning a new smart warehouse or upgrading a traditional warehouse, we provide:

Free field energy flow simulation test

Personalized charging scheme design

7 x 24 hours intelligent operation and maintenance support

Contact our technical team today to get the "Storage Robot Wireless Charging Deployment White Paper" and unlock your efficiency transition solution! Let each robot get rid of "electricity anxiety", and help your warehousing and logistics network truly "never stop"!