WIRELESS CHARGING IN THE NEWS

The wireless charging system developed by WIRELESSPT can effectively address the pain points of traditional contact charging, achieving a comprehensive improvement in charging efficiency, safety and scene adaptability. Through magnetic resonance coupling technology, there is no electric spark throughout the charging process, which extends the equipment's lifespan and reduces operation and maintenance costs. This system has been empirically verified in the inspection scenario of a large coal conveying pipe gallery in Northwest China.

Inspection robots, wireless charging piles, wireless charging solutions, wireless charging for robots

Wireless charging solution for WIRELESSPT inspection robots

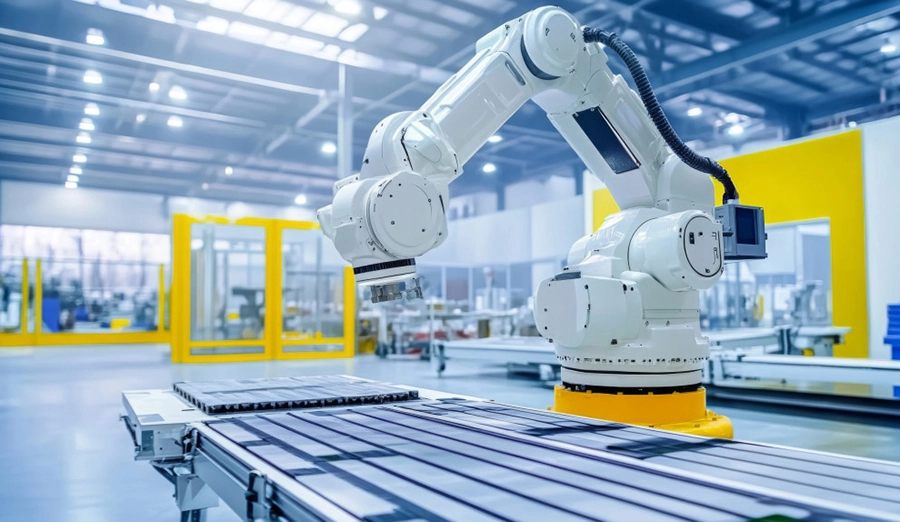

In complex industrial scenarios such as petrochemicals, underground mines, and power energy, intelligent inspection robots are becoming core equipment for ensuring production safety and efficiency. However, traditional contact charging solutions have long faced pain points such as high safety risks, high operation and maintenance costs, and poor environmental adaptability due to exposed metal contacts, frequent plugging and unplugging operations, and the need for manual intervention. In response to these pain points, WIRELESSPT has launched a wireless charging system for inspection robots. Through non-contact energy transmission, intelligent dynamic regulation and modular design, it achieves a comprehensive improvement in charging efficiency, safety and scene adaptability.

The scenario-based pain points of traditional charging solutions

In extreme environments with flammability, explosiveness, high humidity and much dust, the shortcomings of traditional contact charging are particularly prominent. For example, the electric sparks generated by the charging contacts in the chemical industrial park may become the fuse of an explosion accident. The humid environment underground in mines is prone to cause oxidation and short circuits of metal contacts, resulting in robot downtime. The high-temperature vibration in the metallurgical workshop accelerates the mechanical wear of the charging interface, significantly shortening the service life of the equipment. According to industry research, the charging failure rate of traditional solutions under complex working conditions exceeds 15%, and contact faults account for more than 30% of robot operation and maintenance problems. In addition, manual plugging and unplugging for charging requires dedicated personnel to be on duty, which increases the average annual labor cost of a single park by over 200,000 yuan, seriously restricting the efficiency of inspection and economic benefits.

The innovative breakthrough of WIRELESSPT: Magnetic resonance coupling technology

In response to the core demands of industrial scenarios, WIRELESSPT discards the physical contact charging logic and adopts magnetic resonance wireless transmission technology. This scheme realizes energy transfer through the magnetic field resonance of the coils at the transmitting end and the receiving end, and the effective transmission distance is as high as 10cm. Compared with the traditional solution, its advantages are reflected in three dimensions:

1. Intrinsically safe: There is no electric spark throughout the charging process. It has passed explosion-proof certification (Ex mb ⅡC T6 Gb, Ex mb IIIC T80℃ Db gas and dust dual certification) and IP67 protection level, and is suitable for Class II hazardous areas such as chemical plants and mines.

2. High efficiency and reliability: When the robot enters the charging area, it automatically identifies and supplies power. It supports operation within a wide temperature range from -40℃ to 60℃, and the charging efficiency remains stable at over 93%.

3. Low-maintenance design: The non-contact structure avoids mechanical wear, extends the equipment's lifespan, and reduces operation and maintenance costs by 60%.

Scenario-based application and empirical value

In the inspection scene of a large coal transportation pipe gallery in Northwest China, the Luyu wireless charging pile has achieved wireless power supply. It can charge normally in extremely low and high temperature environments and work normally under wind, sun and rain. After the introduction of this solution in a certain coastal petrochemical base, the explosion risk hidden dangers in the charging process were completely eliminated, and the average daily effective working hours of the robots were increased. In addition, the application of the railway tunnel scenario shows that the "stop and recharge" feature of the robot has shortened the full coverage inspection cycle of the tunnel by 57%, significantly improving the timeliness of equipment health monitoring.

The WIRELESSPT wireless charging solution not only addresses the basic charging issue but also achieves digital extension through an energy management platform. The system can monitor the charging status in real time and analyze energy consumption data. And through the "de-touchpoint" design, it provides a safer and more economical energy supply path for industrial inspection robots. Against the backdrop of Industry 4.0 and digital transformation, this technological breakthrough not only resolves common industry challenges but also redefines the boundaries of continuous equipment operation. As robots break free from the constraints of charging cables, the ultimate goal of all-weather unmanned inspection is accelerating its realization. In the future, Luyu will continue to focus on magnetic resonance technology, promoting more industrial equipment to enter the "wireless" era and injecting innovative impetus into global intelligent manufacturing.