WIRELESS CHARGING IN THE NEWS

The wireless charger for the WIRELESSPT Space crawler-type photovoltaic cleaning robot is an important innovation in the field of photovoltaic cleaning. It has solved many problems of traditional charging methods and provided a strong guarantee for the efficient operation of photovoltaic power stations.

The wireless charging solution for dry-hanging photovoltaic cleaning robots represents a major innovation in the field of photovoltaic cleaning. It not only overcomes the limitations of traditional charging methods, enhances the working efficiency and reliability of dry-hung photovoltaic cleaning robots, but also provides strong support for the intelligent maintenance of photovoltaic power stations.

The wireless charging solution for the intelligent inspection robot of the computer room track is an efficient, reliable and safe charging solution. It provides strong support for the intelligent operation and maintenance of the computer room and will drive the operation and maintenance level of the computer room to a new stage.

The wireless charging solution for livestock breeding robots provides strong technical support for smart breeding and will promote the development of the livestock industry towards intelligence and modernization. We believe that with the assistance of wireless charging technology, livestock breeding will embrace an even brighter future.

The wireless charging solution for the intelligent poultry feeding robot of Yucheng Space-Time, with its outstanding performance and innovative design, has brought a brand-new charging solution to the poultry farming industry. It not only addresses the pain points of traditional charging methods, but also enhances the efficiency of breeding, reduces costs, and improves the stability and reliability of the equipment.

Against the backdrop of the rapid advancement of Industry 4.0 and logistics automation, reliable energy supply solutions have become the key to enhancing the performance of smart devices. With solid technological accumulation and mature industrial design, WIRELESSPTSpacetime has provided a set of efficient, safe and stable wireless charging solutions for four-way shuttle vehicles, helping enterprises build more continuous and intelligent warehousing and logistics systems.

The wireless charging solution for intelligent four-way shuttle robots represents a significant innovation in the logistics and warehousing industry. It not only overcomes many drawbacks of traditional wired charging methods, enhances the utilization efficiency and lifespan of intelligent four-way shuttle robots, but also brings a more efficient, safe and convenient charging experience to warehousing operations.

In the future warehousing and logistics field, the application of pallet four-way shuttle vehicles will become increasingly widespread, and the charging methods will also continue to be innovated and improved.

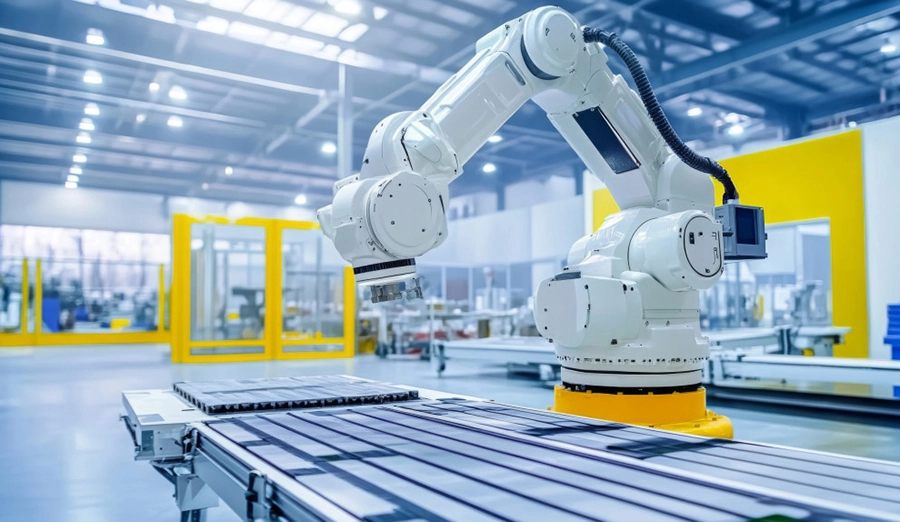

Under the major trends of Industry 4.0 and intelligent manufacturing, the intelligence and automation of industrial equipment are getting higher and higher. Wireless charging, as one of the key technologies, its professionalism will directly affect the efficiency and quality of the entire industrial production.

On the road of future development, WIRELESSPT Energy will continue to uphold the brand philosophy of innovation, quality and cooperation, and constantly enhance its technological strength and service level.

The future of industrial wireless charging technology is full of infinite possibilities. With its continuous technological breakthroughs and profound insights into the industry, Lu Yu Energy is leading the transformation of the industrial wireless charging industry.

In the context of Industry 4.0 and intelligent manufacturing, wireless charging technology is undoubtedly the key driving force for the development of future factories.