WIRELESS CHARGING IN THE NEWS

The popularity of AGV wireless charging stems from its revolutionary efficiency improvement and operation and maintenance model innovation, which is quietly changing the rules of the game in the field of intelligent manufacturing and logistics.

The implementation of AGV wireless charging mainly focuses on energy transmission technology and working scenarios, and different schemes have their own characteristics in efficiency, cost, adaptability and other aspects.

The secret of AGV wireless charging is hidden in an invisible energy transmission system, which acts like a magician to inject electricity into the moving robot.

AGV wireless charging is a technology that allows automatic handling robots to replenish energy without plugging in and unplugging cables, just like the "industrial enhanced version" of wireless charging for mobile phones.

AGV wireless charging is like building an "invisible charging station" for the robot car - no plug, no bare electrodes, when the car passes through a specific area, electricity is quietly injected into the battery. The magic behind this is actually a combination of electromagnetic induction and precision control.

The same wireless charging pile can be adapted to different brands of devices, and the voltage requirements are automatically identified through the NFC protocol.

High-end models such as the Aiper Surfer S1 Pro are equipped with IPX8 waterproof wireless charging module, which uses electromagnetic induction principle to achieve non-contact charging.

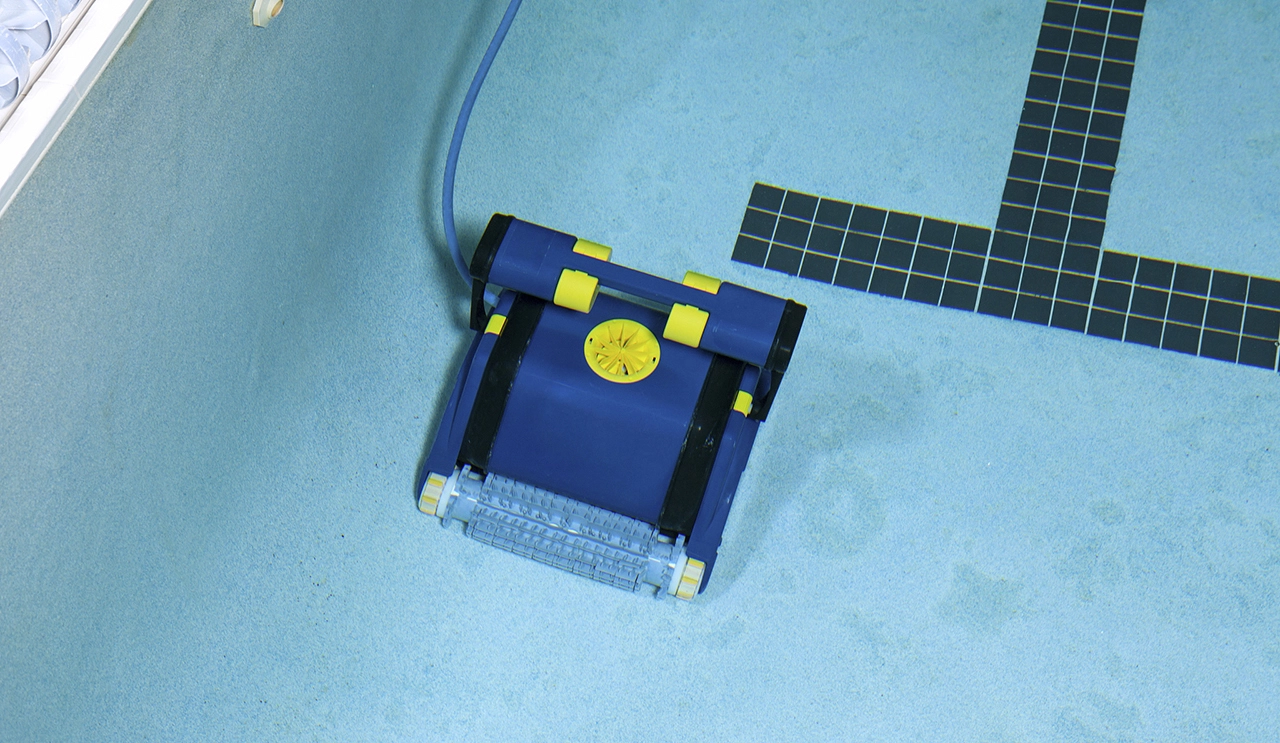

The swimming pool cleaning robot is an intelligent device used to automatically clean the swimming pool, aiming to replace the traditional manual cleaning method, and efficiently complete the dirt cleaning, debris collection and water quality maintenance tasks in the bottom of the pool, the pool wall, the steps and other areas through mechanization and intelligent technology. Its core function is to reduce manpower, improve cleaning efficiency, and ensure that the pool is in a healthy state for a long time.

At present, UAVs mainly supplement energy through the following ways, and the technical path is limited by battery technology, use scenarios and cost factors:

The classification of robot forms is mainly based on its physical structure, movement mode and environmental adaptability. Different forms determine the functional boundaries of robots in specific scenes. The following are the main categories and typical representatives:

Embodied AI Robot is the product of the deep integration of artificial intelligence and robotics in recent years, and its core idea is to allow the agent to interact with the environment through "embodied" (that is, having a physical entity), so as to achieve learning, perception and decision-making abilities closer to humans.

Charging efficiency is the key factor restricting the popularization of wireless charging technology. At 3-10cm transmission distance, the overall efficiency of the current mainstream scheme can reach 85%-92%, close to the level of wired charging, and its technological breakthrough mainly relies on three major innovations: